Needle-punched geotextiles are versatile synthetic fabrics widely used in civil engineering and environmental applications. They are manufactured by a process known as needle punching, which involves entangling fibers together using barbed needles to create a robust and nonwoven fabric. Here are some key aspects of needle-punched geotextiles:

Composition

- Materials: Typically made from polypropylene, polyester, or other synthetic fibers, needle-punched geotextiles exhibit excellent durability and resistance to various environmental conditions.

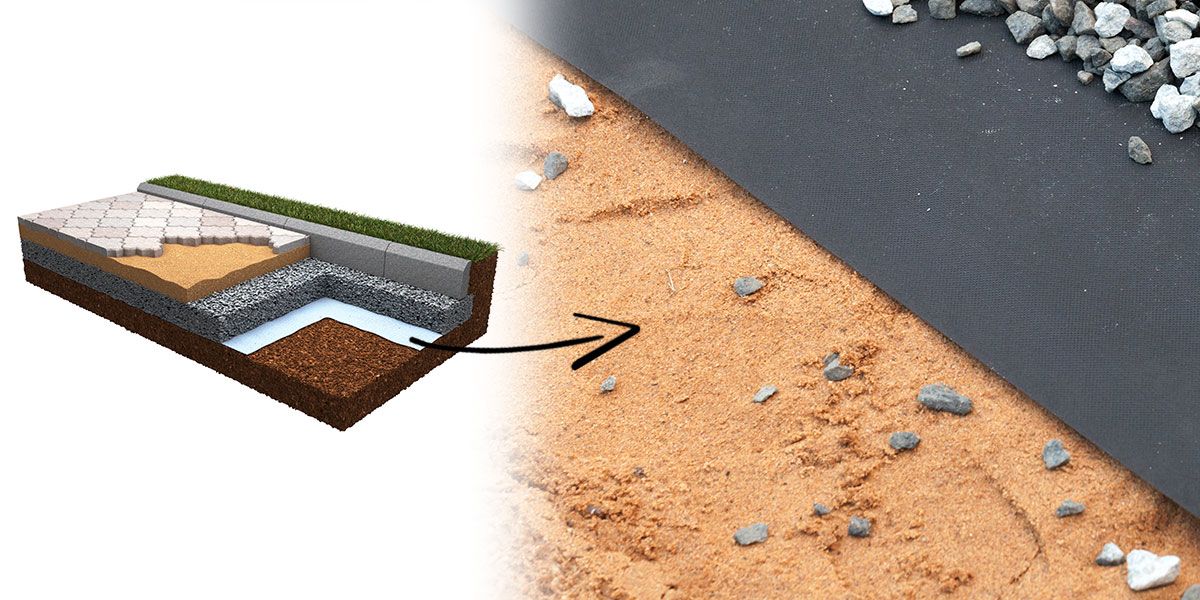

- Structure: The needle punching technique creates a matrix of interlocking fibers, resulting in a porous textile that allows for drainage while retaining soil particles.

Characteristics

- Permeability: They have high permeability, enabling water to flow through while filtering out fine particles, which helps in controlling erosion and maintaining soil stability.

- Strength: The process of needle punching endows these geotextiles with significant tensile strength and resistance to tearing, making them suitable for applications that require robust materials.

- Non-biodegradable: Being made from synthetic materials, needle-punched geotextiles do not decompose, providing long-lasting solutions in construction and landscaping.

Applications

- Erosion Control: Used to stabilize slopes and embankments, preventing soil erosion in agricultural and civil engineering projects.

- Filtration: Employed in drainage systems to filter out sediments while allowing water to pass, used in applications such as landfills, drainage ditches, and roads.

- Separation and Reinforcement: Serves as a separating layer between different soil types to prevent mixing, and enhances the load-bearing capacity of underlying soil layers in road construction.

- Geocomposites: Often combined with other materials to create geocomposite systems for specific applications, such as reinforced earth structures.

Advantages

- Cost-effective: Compared to traditional materials such as gravel or sand, needle-punched geotextiles offer a lighter and more economical solution.

- Easy Installation: They are generally easy to handle and install, making them a preferred choice for many construction projects.

- Versatile: Available in various thicknesses and strengths, they can be tailored to suit specific project requirements.

In summary, needle-punched geotextiles represent an innovative solution in the field of geotechnical engineering, offering a blend of strength, durability, and functionality across various environmental management and construction applications.

Post time: Apr-11-2025